ECOHYDRAULIC since 1989. Because the focus,so professional.

Aluminum shavings chips briquette making machine (Y83L-360)

Aluminum shavings chips briquette making machine (Y83L-360)

Ecohydraulic aluminum shavings briquette making machine can help you make your aluminum waste worth more. Aluminum scrap metal,in the form of turnings,filings,chips and shavings,is produced every day of production,piling up on the equipment and floor. While aluminum and fluids waste can be costly to dispose of and difficult to reuse without processing,aluminum briquetting allows manufacturers to both eliminate costs and create a new revenue.

Y83W-630 horizontal steel chips metal scrap briquetting press

Y83W-630 horizontal steel chips metal scrap briquetting press

There are many problems in the recovery of steel chips directly into the furnace,steel briquetting press machine is especially for hard chips like steel,the recycling of steel chips reduces the production cost of foundry enterprises and greatly improves the market competitiveness of the enterprises. The steel scraps are small,loose,directly into the furnace will be seriously blocked,the material block clearance is the furnace gas rising channel,directly affect the smelting process,the loose steel scrap without pressing,extremely easy to float on the furnace lining,corrosion lining,and large loss of raw materials will cause low molten iron rate.

Y83-360 scrap iron metal filings block making machine

Y83-360 scrap iron metal filings block making machine

Y83 series metal briquetting press are industrial machines designed to make maximum use of metal swarf such as cast iron,aluminum,copper,steel,brass,zinc,bronze,titanium and magnesium,they are also suitable for other machining scraps by pressing them into briquettes. It results in economic benefits for companies that generate the swarf,companies that recycle metal scraps,and for foundries that process the scraps. Also there is environmental benefits resulting from the briquetting process.

Y81T-250 push-out scrap sheet metal car shell baler machine

Y81T-250 push-out scrap sheet metal car shell baler machine

The scrap metal baler machine is used to compress scrap metal (steel,copper,aluminum,stainless steel,etc)into metal block or metal bale. The purpose is to save the transportation cost or reduce the raw material loss when smelting. After compressing,the metal bale is easy to transport and store,so it can save transporation cost,reduce storage area and reduce the loss when smelting.

Y81F-200 manual waste iron steel aluminum metal shavings baling machine

Y81F-200 manual waste iron steel aluminum metal shavings baling machine

The Hydraulic Metal Baler is used for cold press metal scraps within 6-8mm in thickness under most circumstance. The processable material includes scrap steel,waste containers and disintegrated vehicle shell etc. After cold pressing into block,it is convenient for storage and transportation or putting into furnace. Hydraulic Metal Baler working principle: The metal scraps and other materials are placed in the workbin. The hydraulic cylinder works to suppress the pressure. The baled material is compressed and formed into various metal blocks.

Y83L-630 hydraulic aluminum steel turnings chips vertical briquetting machine

Y83L-630 hydraulic aluminum steel turnings chips vertical briquetting machine

We have found a way to not only reduce volume,but also add a value to scrap made by production processes while recuperating lubricants with our compact Briquetting machine. Our Briquetting Machine is suitable for most industrial materials such as steel,cast iron,aluminum,copper,brass,zinc,bronze and plastic scrap.

135ton forward-out aluminum cans sheets baling press for sale

135ton forward-out aluminum cans sheets baling press for sale

Aluminum Cans Baler Machinery is a machine suitable for baling and packing various aluminum cans. It is idea equipment for recycling various metal cans. The cans baler Press Machine press kinds of cans,includes ubcs,aluminum cans,tin cans etc. Baling loose cans into high density bales,to save storage and delivery space.

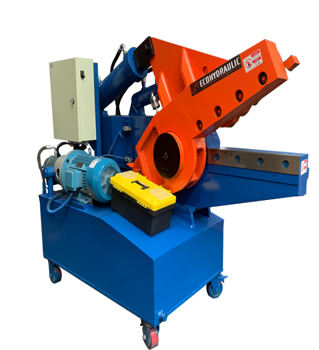

Q08-100 hydraulic metal steel tubes pipes bar alligator shear

Q08-100 hydraulic metal steel tubes pipes bar alligator shear

Yejin alligator shear cut scrap metal into smaller pieces and help to separate different materials types,earning you more money from your scrap metals. Alligator shears are ideal for waste materials recycling processing industries,scrap metal (iron,steel,steel pipe,etc.) cold shearing to different section forms of middle and small steel factories.

Our products are not only popular in China,but also have market shares in more than 20 Countries,for example,Russia,Serbia,Japan,Thailand,Malaysia,Vietnam,Saudi Arabia,Dubai,Oman,India,America,Mexico,Brazil,Argentina,Kuwait,Indonesia,Canada and Columbia.

Established in

square meters cover an area

Professionals among them

Exporting country

Obtain national patent

Staff members

We are manufacturer with own factory for more than 30 years.

With professional design and sales team,we can serve you the perfect solution with lowest cost.

Welcome to inspect any time,we are near Shanghai airport.

With many stock models,and for briquette machine,we can deliver all models in one month.

Please Keep An Eye On The Developments Of Our Company

“excellent Quality, Perfect All" Is Company's ,squality Policy, And All Staff,s Working Direction "be Honest' Is The Core Idea For Us To Contribute" Century "Company"

Copyright © Jiangyin Metallurgy Hydraulic Machinery Factory All Rights Reserved | Blog | Privacy Policy