Selecting the Right Shears for Metal Cutting

Having the right tools can be crucial when you are cutting metal. The most common tool used for this purpose is none other than a pair of shears, designed specifically to snip through metal sheets at an accurate and precise manner. There is more to say about shears so let us go further into this world with your metalworking projects now in considerations.

It is for this reason that choosing the correct shears to perform your metal cutting tasks with utmost care and attention. Different Types of Shears: Just like scissors, shears are designed for cutting something specific. Some shears you can choose may have straight blades that offer better performance for getting precise cuts, while others are equipped with curved edges and they also make tough metals easy to cut. A balanced length of the blades - DC shears are preferable for thicker metalsPatented blade geometries -- longest in industryThe appropriate size of knives, given that shorter ones are better at higher performance and inside cuts.

It matters how good the shears themselves are, because this is going to have a big impact on what kind of work you can produce through metalworking. Selecting for stainless steel as the shear material provides long-term usage life and ensures that DIY garden shears can cut with accuracy. Comfort is equally important, you should not neglect your handles here because ergonomically designed hand can help to avoid muscle tiredness even after working hours and improve the quality of work.

The different gauges of metal make it required to have shears suitable for the width. Light duty shears cut thinner sheet metals with precision and control, while heavy duty shears feature stronger blades of increased length to enable cutting of wide leaves as well as longer handles that exert more mechanical leverage for thicker metal sheets.

Keeping Safety First and Accuracy Second

Ensure that the metal sheet is clamped in place before you start any cuts, this will stabilize them and maintain a clean and accurate cut. This helps not only to stop slipping but also offers accurate cutting, particularly when handling much heavier steel linens. Purchasing high-quality shears not only saves time on your metal projects but also enhances safety by reducing the chances of mistakes and injury.

If you are not sure of what best sheers suit your project, feel free to ask professionals. They are expert in this domain and their suggestions will help you choose the perfect set of shears based on your specific metalworking needs from which excellent outcomes can be expected with high standard performance.

Conclusion Shear Selection Guide

To sum it All up, the steps to pick right shears can make a huge difference for not only metal cutting process but overall Success. Even if you work with thin slices of metal or thick, straight lines to curved ones - any high-quality shear can the standardize your projects and optimize them in terms of precision. Transform your metalworking game and elevate the quality of final products you produce by choosing a best suited shears as per requirement.

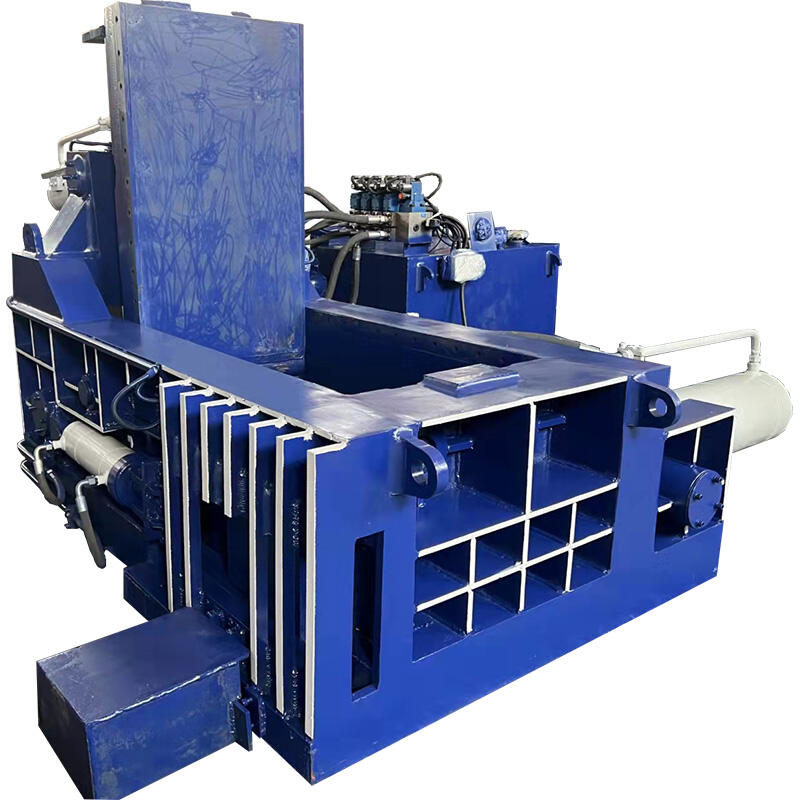

We offer a variety of hydraulic machines, such as hydraulic Briquetting presses, hydraulic balers and hydraulic alligator shears. Our products are used in various industries such as foundries and steel mills. They also are used for construction, energy production, scrap metal recycling, and in the automotive industry. Our equipment is suitable for many industrial applications because of its flexibility.

In 1989, Jiangyin Metallurgy Hydraulic Machinery Factory has more than 30 years' experience in the hydraulic machinery industry. We are well known in the domestic scrap recycling industry due to our deep-rooted experience and constant expansion. Our presence on the market has successfully expanded to more than 30 countries, including Russia, Brazil and Japan. This reflects our strength and credibility within the field.

At Jiangyin Metallurgy Hydraulic Machinery Factory Our customers' satisfaction is our first priority. We provide flexible and custom solutions to meet the particular needs of our customers. Our after-sales service is always available to assist you, whether you have any questions regarding the performance of your equipment or need assistance in troubleshooting. From purchase to installation We are committed to giving a seamless and effective service to our customers.

Two of our state-of-the-art facilities, spanning 30,000 square meters are fitted with cutting-edge technology, and run by a dedicated staff of over 150 professionals, including 17 experts. We pride ourselves on our outstanding capability in research and development, demonstrated by the twelve national patents that we own. This commitment to innovation ensures that we always provide high-quality and reliable hydraulic machinery solutions.

Copyright © Jiangyin Metallurgy Hydraulic Machinery Factory All Rights Reserved | Blog | Privacy Policy