Have you noticed cars emitting smoke when they are in motion? Instead, all this smoke is just a mixture of nasty chemicals that attacks our ecosystem and can poison us and other mammals. The preservation of our air, both clean and breathable, is necessary for the continuation of life on Earth. But luckily, there exists a special technology that assists with this known as the cutter pipe. This technology is crucial in decreasing the harmful gases emitted by cars. In this article, we are going to look at what a three-way catalyst shear is as well as why it plays such an important role in ensuring that our air remains clean. We will also discuss how it works, the varieties of these devices, and what enhancements we might expect in the future.

The three-way catalyst is a mixture of special materials which can be composed of either platinum, rhodium, or palladium. These substances behave like a sponge that absorbs the harmful gases before they leave the exhaust of the car into the atmosphere. Due to this, the gases released from the exhaust are considerably far safer and cleaner for our environment. This ensures clean air for all of us to breathe.

The shear of the three-way catalyst is critical for safeguarding our planet and our health.” Toxic gases that are released into the atmosphere can lead to issues such as smog, acid rain and respiratory illnesses like asthma. Asthma makes it difficult for people to breathe, so lowering these harmful gases should be a real priority.” The tin shear can decrease these harmful gases by as much as 90 percent. This means that also, when you drive a vehicle with three-way catalyst shear, car emissions are kept cleaner thus creating safer air and environment for indirect and direct surrounding entities.

You know I'm specialized in some kind of chemical reaction which is used on three-way catalytic shear. As the harmful gases pass, they adhere to the surface of the catalyst. Then, the catalyst converts these toxic gases into less harmful substances. Carbon monoxide, for instance, is converted to carbon dioxide; hydrocarbons are converted to water and carbon dioxide; nitrogen oxides are reduced to nitrogen and oxygen.

The chemical reaction needs the proper mixture of oxygen and fuel. The fuel is the gasoline or diesel that fuels the automobile; the oxygen, from air that enters and goes through with it. The three-way catalyst shear also will not do its job as well when the mix of oxygen and fuel is too rich or thin. This suggests the engine needs to be well running, such that the shave from three way catalyst can work.

There are two varieties of three-way catalyst shear: close-coupled catalysts and underbody catalysts. Close-coupled catalysts are placed close to the engine, so they can begin their work quickly — even from a cold start. This is extremely beneficial because it suggests that the car can start eliminating harmful emissions straight away. In contrast, underbody catalysts are larger and located farther from the engine. The larger gas flow allows them to accommodate more exhaust, making it beneficial for bigger vehicles

With advancing technology comes better three-way catalyst shear. Jiangyin Metallurgy, a major manufacturer of catalyst materials, designs new and improved three-way catalyst shears. It includes researchers who are working to develop catalysts that will function at lower temperatures. That means they can start cutting emissions sooner, which is good for the planet. They are also targeting stronger, more durable catalyst materials that can survive longer and withstand damage better.

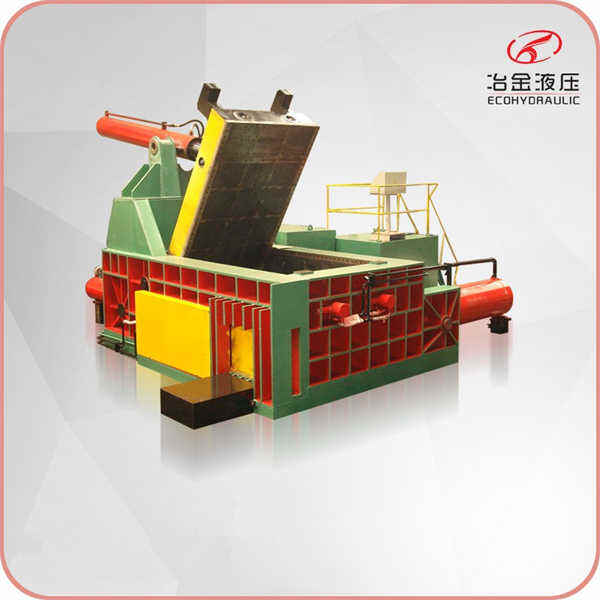

The two modern facilities covering 30 000 square meters are fitted with cutting-edge technology They are also Three-way catalyst shear with an experienced team of more than 150 professionals including 17 specialists We pride ourselves on our strong capabilities in research and development evidenced by the 12 patents that we have in the national system Our commitment to innovation allows us to consistently provide high-quality efficient hydraulic machinery

Jiangyin Metallurgy Hydraulic Machinery Factory established in Three-way catalyst shear has over 30 years of expertise in the hydraulic industry Our long-standing expertise and steady growth has established us as a prominent name in the domestic scrap recycling industry for metal Our market presence has now been expanded to more than 30 countries including Russia Brazil and Japan This is a testament to our leadership and reliability within the business

At Jiangyin Metallurgy Hydraulic Machinery Factory Three-way catalyst shear is our top priority. We provide flexible and custom solutions to meet the specific needs of our clients. Our after-sales staff is always available to offer support, whether it's answering questions about the operation of the equipment, or providing help with troubleshooting. From purchase to installation our team is committed to giving a seamless and effective experience for our customers.

We provide a wide range of hydraulic machines such as hydraulic Briquetting presses hydraulic balers and hydraulic alligator shears Our equipment is designed to be used in Three-way catalyst shear across various industries including steel mills foundries construction the automotive sector energy generation scrap metal recycling Our equipment is versatile making it the perfect choice for a wide array of industrial requirements

Copyright © Jiangyin Metallurgy Hydraulic Machinery Factory All Rights Reserved | Blog | Privacy Policy