- přehled

- Parametry

- Vlastnosti

- Dotaz

- Související produkty

| Místo původu: | Jiangyin, Čína |

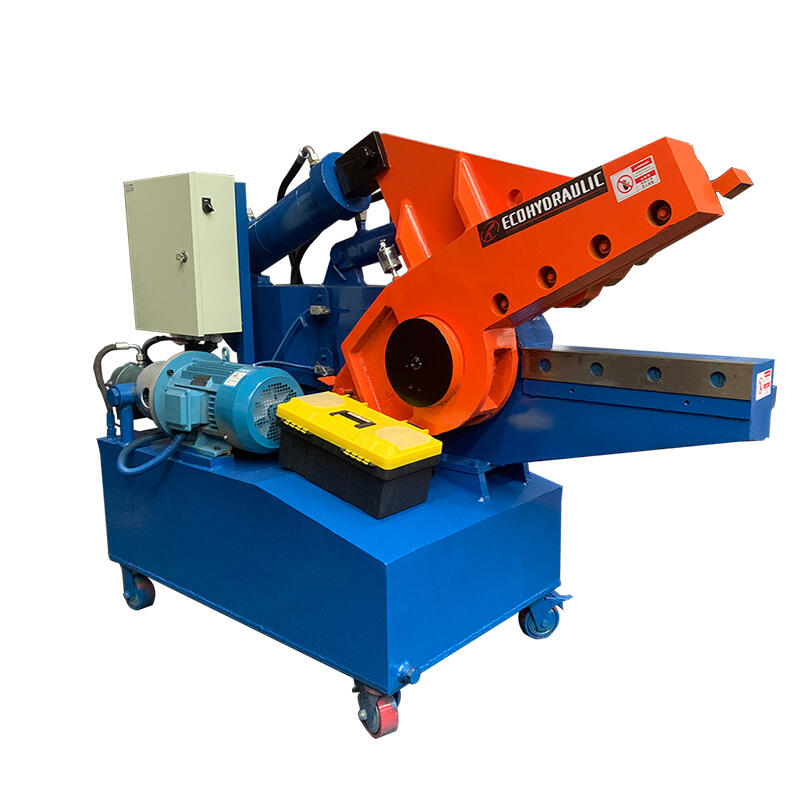

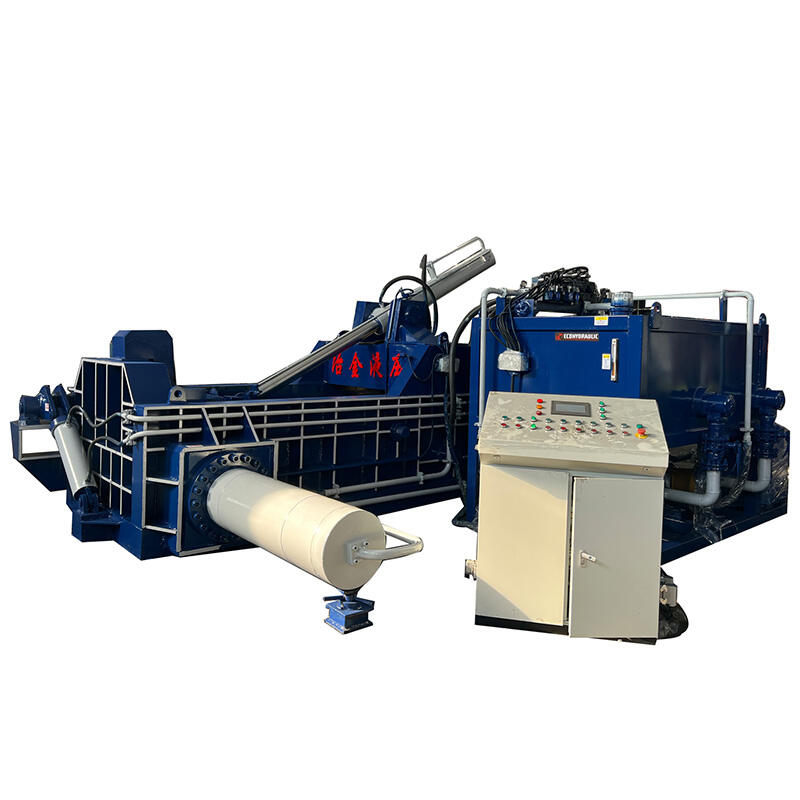

| Název značky: | Ecohydraulic |

| Typ modelu: | Y83L-360 |

| Certifikace: | ISO, CE |

| Minimální objednávková velikost: | 1 sada |

| Cena: | FOB Šanghaj, USD20000~USD25000 |

| Podrobnosti o obalu: | Nahé balení |

| Doba dodání: | 3 dny (skladem) |

| Podmínky platby: | 100%TT před naložením |

| Dodací schopnost: | 30 sad/měsíc |

Aplikace

Kromě drátů vzniká během metalurgického zpracování také bláto, kombinace malých hliníkových částic a tekutin použitých během procesu. Stejně jako u drátů je úložiště a správa bláta obtížná ve výrobních zařízeních, vyžaduje více kroků, které mohou zabírat více času, úsilí a zdrojů, než má většina výrobců k dispozici.

Přestože může být zlikvidování hliníku a kapalných odpadů nákladné a obtížné je znovu využít bez zpracování, existuje často přehlížené řešení v tvaru tlačení destiček. Tlačení hliníkových destiček umožňuje výrobcům eliminovat náklady související s likvidací odpadů a vytvořit nový zdroj příjmů.

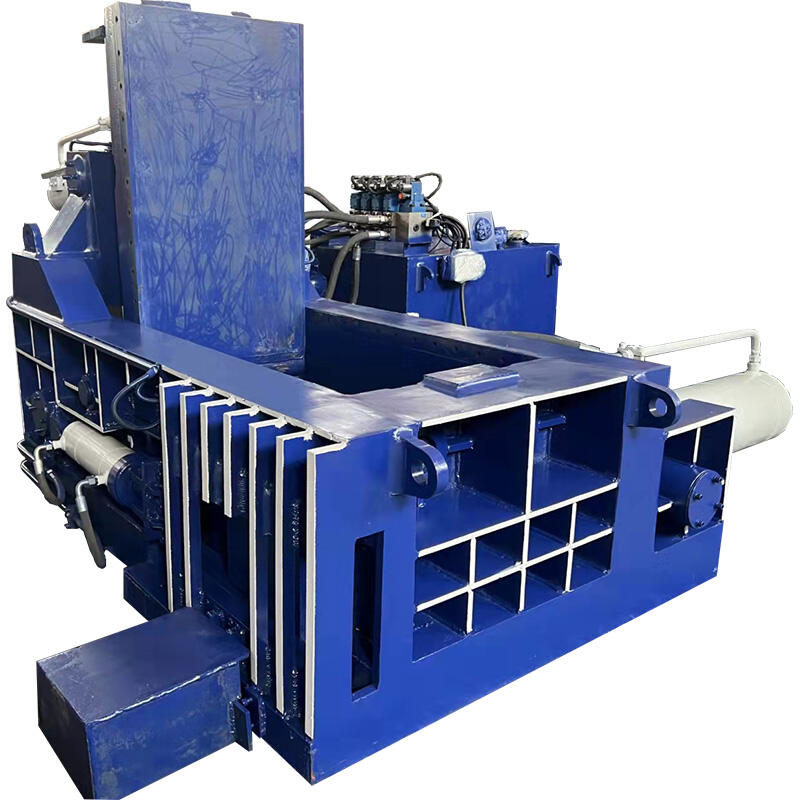

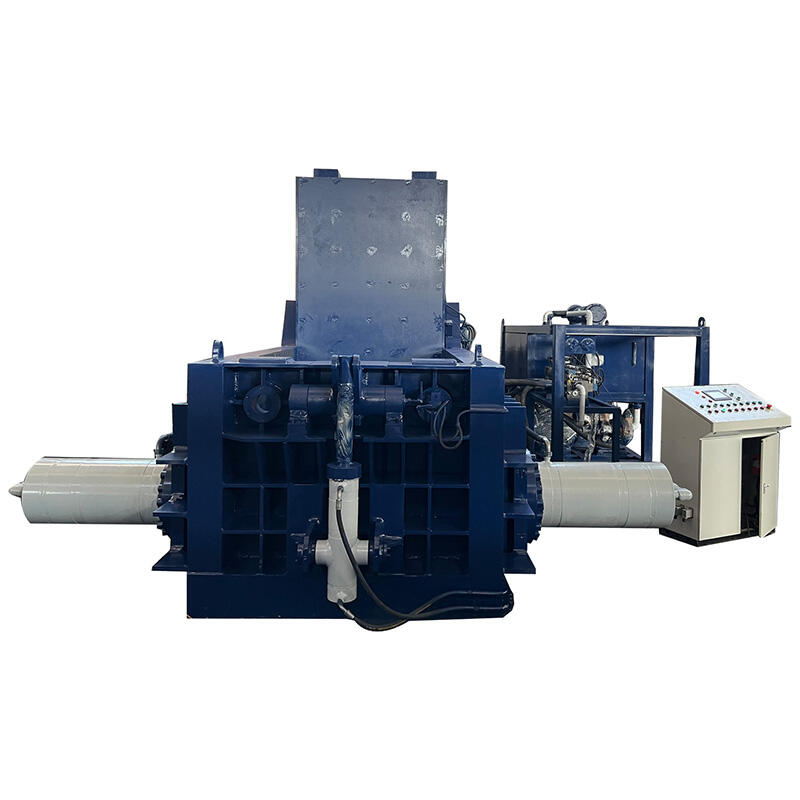

Stlačovací zařízení na hliníky od Ecohydraulic přeměňují držadla na malé cihly, které lze snadno ukládat, odstraňovat a dokonce prodávat. Toto pomáhá výrobcům obnovit hodnotu z jinak nákladných odpadních produktů z hliníku. Každý systém na stlačování používá hydrauliku k kompresi hliníkových odpadků do hustých cihel a oddělení jakéhokoli kapalného prostředku použitého v procesu metalurgie od samotných odpadků. Cihly vytvořené systémy na stlačování od Ecohydraulic jsou snadno transportovatelné nebo ukládatelné a méně pravděpodobně bude docházet ke korozím, což zvyšuje jejich prodejní hodnotu. Drahé zpracovatelské kapaliny vytlouknuté během procesu umožňují výrobcům je znovu použít nebo recyklovat podle svého uvážení.

Specifikace

Výhody implementace systému na tvoření hliníkových briek z odpadků jsou rozsáhlé. S mnoha výrobci, kteří se snaží zlepšit své finanční výsledky, nabízejí stlačovače od Ecohydraulic společnostem způsob, jak:

1) vyťukat hodnotu z hliníkových odpadků;

2) obnovit cenný plošný prostor;

3) udržovat pracoviště čisté a bezpečné;

4) eliminujte nákladné poplatky za likvidaci.

| Model | Y83L-250 |

| Nominální síla | 2500 kN |

| průměr briquet | D100mm |

| hustota briquet | ≥ 2.1t/m³ |

| váha briquet | 1~2KG |

| Produktivita | 3~4blok/min |

| výstup za jednu směnu | 2~3t/8h |

| Celkový výkon | 22KW |

| Hmotnost stroje | asi 5,5 tun |

| Celkový rozměr | strojová základna: 1470*2290*3500mmbenzínová nádrž: 1350*1300*1160mm |

Služba

1) zdarma překlad dokumentace k produktu do vašeho jazyka, bez starostí provozovat a udržovat.

2) Inženýři k dispozici pro servis strojů za hranicemi.

3) Databáze zákazníků se všemi záznamy zákazníků.

4) Technická telefonní služba 7×24.

5) Garance na jeden rok a lifelong údržba.

6) Zásoby dílů: jedna sada náhradních dílů zdarma, nářadí, operační kniha.

Často kladené otázky

1) Jste továrna nebo obchodní společnost?

Jsme výrobce s vlastní továrnou již více než 30 let.

2) Jak mohu vaší firmě důvěřovat?

A. S profesionálním designem a prodejním týmem vám můžeme nabídnout dokonalé řešení za nejnižší náklady.

B. Posouzeno nezávislou stranou, národní patenty na veškeré vybavení.

C. Jsme přístupní kdykoli k prohlídce, nacházíme se blízko letiště v Šanghaji.

D. Co se týče strojů, jsme první výrobci tlačidel na tlačenici, hydraulických balicích strojů, všechny další produkty jako je šreddery jsou také našimi hlavními produkty.

3) Je vaše cena konkurenceschopná?

Určitě vám nabídneme nejlepší tovární cenu založenou na vynikajícím produktu a službách.

Kontaktujte nás, chcete-li dozvědět více o tlačení hranolů z aluminia ve vašich prostorách.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

AZ

AZ

LA

LA

UZ

UZ