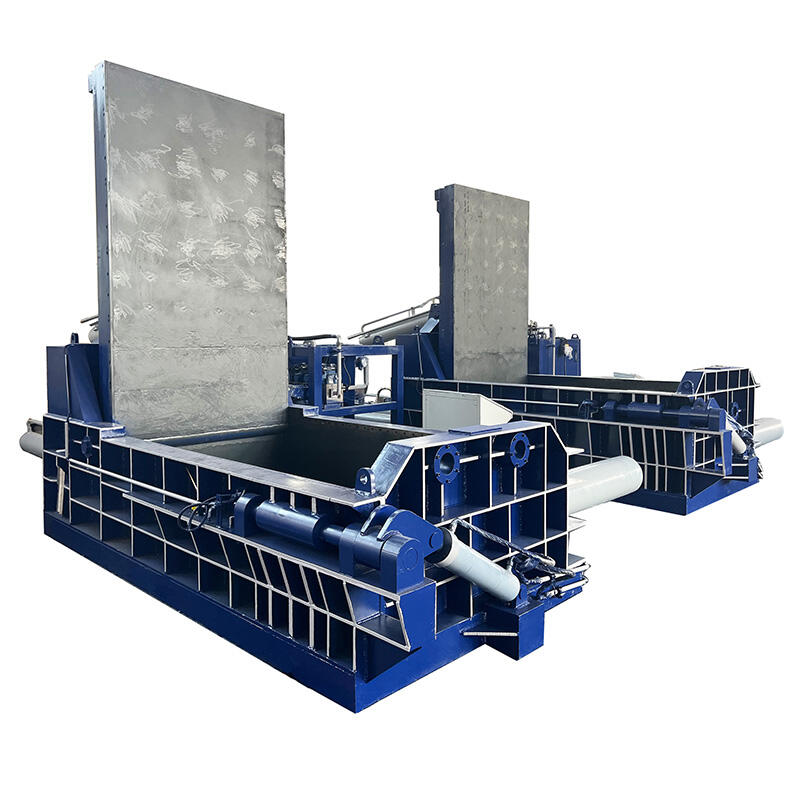

Μια πιεστική μηχανή για αποβλήτα είναι μια μεγάλη μηχανή που σχεδιάστηκε για να συμπιέζει τα απόβλητα σε μικρά πακέτα, γνωστά κυρίως ως Bales. Είναι σημαντικά ευκολότερο να μεταφερθούν και να αποθηκευτούν αυτά τα πακέτα και να ανακυκλωθούν από τα άδεια απόβλητα. Επειδή τα κέντρα ανακύκλωσης μπορούν να συμπιέσουν περισσότερα απόβλητα σε μικρότερο διάστημα και επίσης να παράγουν λιγότερα απόβλητα σε σύγκριση με άλλες πιεστικές μηχανές, αυτό είναι ένα μεγάλο βοντήγι, καθώς αυξάνει σημαντικά την αποτελειωτικότητα της ανακύκλωσης και επομένως εξοικονομεί χρήματα.

Υπάρχουν διάφορες είδη απόβλητων υλικών με τα οποία μπορούμε να εργαστούμε μέσω μιας προτεινόμενης τεχνολογίας που ονομάζεται μηχανέματα κυβωτοποιητή και αυτά τα τύποι μηχανών έχουν εισαχθεί για να συμπιέσουν το υλικό σε μπάλες και στοίβες. Χρησιμοποιούνται για να τρίψουν από αλουμινιού κουτάκια και πλαστικά μπουκάλια, μέχρι παλιές μέρες αυτοκινήτων και διάφορα είδη μετάλλειων αποβλήτων. Αυτές οι μηχανές είναι απολύτως ιδανικές για περιορισμένες διαστάσεις, καθώς η μέγεθος τους είναι μικρός και μπορούν να εγκαθιστούν ακόμη και σε μικρότερα κέντρα ανακύκλωσης. Εν τω μεταξύ, η υπεριορετική ισχύς των μερών εξασφαλίζει ότι εκτελούν το έργο τους αποτελεσματικά για να επεξεργαστούν δύσκολα υλικά.

Εκτός αυτού, η ασφάλεια είναι μια σημαντική παράμετρος για τις μηχανές πακετοποίησης αποβλήτων. Έχουν σχεδιαστεί με συγκεκριμένες λειτουργίες ασφαλείας που βοηθούν να κρατήσουν τους χειριστές ασφαλείς από ατυχήματα και τραυματισμούς ενώ εκτελούν τη λειτουργία της μηχανής. Δεύτερα, αυτές οι μηχανές συνήθως έρχονται με φιλικό σχεδιασμό για τον χρήστη. Σε απλά λόγια, αυτό σημαίνει ότι οι άνθρωποι μπορούν να λειτουργούν και να μείνουν κοντά τους χωρίς δυσκολίες, βοηθώντας έτσι την αποκύκλωση να γίνει πιο εύκολη και ασφαλή.

Για αυτή τη δουλειά, οι μηχανές πακετοποίησης αποβλήτων είναι πολύ σημαντικές. Βοηθούν να μειωθεί ο αποβλητικός ύφειρμα, να μειωθεί η ρύπανση και να εξοικονομηθεί ενέργεια κάνοντας την αποκύκλωση μια πιο εύκολη επιλογή. Επιπλέον, διατηρούν τους πόρους εliminating την ανάγκη δημιουργίας νέων υλικών. Αυτό είναι τόσο κρίσιμο ώστε να μπορούμε να διατηρήσουμε ένα υγιές και βιώσιμο πλανήτη για τις επόμενες γενιές.

Η τεχνολογία της πιέστρικης απορριμμάτων έχει βοηθήσει να επιτευχθεί η μέγιστη αξία με την πίεσή τους σε μικρά και συμπιεσμένα καλάθια. Αυτά τα καλάθια είναι εύκολα και φθηνότερα να μεταφερθούν και να αποθηκευτούν, επιτρέποντας στα κέντρα ανακύκλωσης να επεξεργαστούν περισσότερα απόρριμματα. Αυτό σημαίνει επίσης ότι περισσότερα χρήματα μένουν στις τσέπες των κεντρών ανακύκλωσης για να διεξάγουν τις καλές τους εργασίες.

Η διαχείριση με απορρίψιμα υλικά είναι μια κόπος πράξη. Τα απόρριμματα μπορούν να καταλαμβάνουν πολύ χώρο, ειδικά όταν πρέπει να τα αποθηκεύσετε για μια χρονική περίοδο μέχρι να συγκεντρωθεί αρκετή ποσότητα και κάποιος να τα αγοράσει ή αν τα απόρριμματα σας είναι πολύ ανεπιτάξια και χρειάζονται περισσότερη ταξινόμηση. Συστήματα ανακύκλωσης: Αυτά χρησιμοποιούνται ως προς τη διαχείριση απορριμμάτων.

Τα συστήματα πιεστικών μηχανών για αποβλήτα συμπιέζουν τα απόβλητα σε συμπιεσμένη μορφή, έτοιμα για μεταφορά ή αποθήκευση μετατρέποντάς τα σε πακέτα. Για τα κέντρα ανακύκλωσης, αυτό μειώνει σημαντικά τον χρόνο και το κόστος της διαχείρισης των αποβλήτων. Αντί να ψάχνουν όλη μέρα σε άδεια υλικά, οι εργάτες μπορούν να επικεντρωθούν στην επεξεργασία των πακέτων, που ξανά μειώνει τον χρόνο και μειώνει τα κόστη.

παγίδα αποβλήτων Jiangyin Metallurgy Hydraulic Machinery Factory Η ικανοποίηση των πελατών μας είναι η πρώτη μας προτεραιότητα. Προσφέρουμε ευέλικτες και προσαρμοστές λύσεις για να καλύψουμε τις ειδικές ανάγκες των πελατών μας. Η μεταπωλητική μας υπηρεσία είναι πάντα διαθέσιμη για να σας βοηθήσει, εάν έχετε οποιαδήποτε ερώτηση σχετικά με την απόδοση του εξοπλισμού σας ή αν χρειάζεστε βοήθεια σε προβλήματα. Από την αγορά μέχρι την εγκατάσταση, είμαστε υποχρεωμένοι να παρέχουμε μια αδιάκοπη και αποτελεσματική υπηρεσία στους πελάτες μας.

Οι πιέσεις συμπακτού απορριμμάτων διαθέτουν ευρύ φάσμα υδραυλικού εξοπλισμού, όπως υδραυλικού συμπακτή κουρασίας και υδραυλικού συμπακτού μετάλλων, καθώς και υδραυλικά κοπάκια. Τα προϊόντα μας σχεδιάζονται για να λειτουργούν σε διάφορες εφαρμογές σε διαφορετικές βιομηχανίες, όπως σιδηροποιεία, καστάνες, κατασκευή, τον τομέα των αυτοκινήτων, παραγωγή ενέργειας και ανακύκλωση μετάλλειων απορριμμάτων. Ο εξοπλισμός μας είναι απολύτως κατάλληλος για αρκετές βιομηχανικές εφαρμογές λόγω της πολυειδικότητάς του.

Η εργοστάσιο υδραυλικών μηχανημάτων μεταλλευτικών Jiangyin, ξεκίνησε τις πιέσεις συμπακτού απορριμμάτων το 1989 και είναι εταιρεία με πάνω από 30 χρόνια εμπειρία στον τομέα των υδραυλικών. Η εκτεταμένη μας εμπειρία και συνεχής ανάπτυξη μας έχει καθιερώσει ως εξαιρετικά γνωστό όνομα στην εσωτερική αγορά ανακύκλωσης απορριμμάτων μετάλλων. Έχουμε επεκτείνει την παρουσία μας στην αγορά σε πάνω από 30 χώρες, συμπεριλαμβανομένων της Ρωσίας, της Βραζιλίας και της Ιαπωνίας, αποδεικνύοντας την ηγετική μας θέση και την αξιοπιστία μας στην αγορά.

Τα δύο σύγχρονα εγκαταστήματά μας, που καλύπτουν ένα εμβαδό 30.000 τετραγωνικών μέτρων, είναι αποθετικά για υλικά με την πιο σύγχρονη τεχνολογία.Υποστηρίζονται από ομάδα 150 επαγγελματιών, περιλαμβανομένων 17 ειδικών. Είμαστε υπερήφανοι για τις ισχυρές μας δυνατότητες έρευνας και ανάπτυξης, όπως αποδεικνύεται από τα 12 εθνικά πατέντες που κατέχουμε. Αυτή η αφοσίωση στην καινοτομία εξασφαλίζει ότι συνεχίζουμε να παρέχουμε λύσεις υδραυλικής μηχανής υψηλής ποιότητας και αποτελεσματικότητας.

Copyright © Γεωργική Εργοστάσιο Υδραυλικών Μηχανών Jiangyin. Όλα τα δικαιώματα προστατεύονται | Ιστολόγιο- Τι;Πολιτική απορρήτου