Čo sú kovové balíky?

Priemyselná strojina, kovová balicí strojina, uľahčuje spracovanie základného druhu škodlivín. Škodlivý kov sú kusy kovu, ktoré už pre nás nie sú užitočné, napríklad poškodené spotrebiče alebo staré autá. Jednou z nich je Jiangyin Metallurgy, ktorá vyrábajú tieto stroje. Majú maloformátové kovové balíky, ktoré veľmi dobre fungujú a prispievajú k životnému prostrediu, pretože recykling funguje. Takže sa pozrime na to, ako fungujú kovové balíky a prečo sú pre podnikanie a planétu tak dôležité.

Ako fungujú kovové balíky?

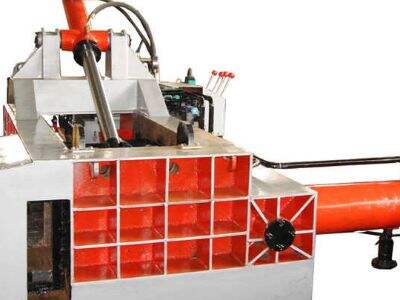

Poznajte, že niektoré kovové balíky sú tiež známe ako kovové kompaktory, ktoré sú strojmi na kompresiu starého kovu do rôznych tvarov pre jednoduchšie odvozenie. Začnete tak, že dát starý kov do balíka. Potom sa z hmotnosti hydraulického tlačidla v rámci stroja spustí a veľmi silne stlačí kov. Táto kompresia skrátka kov podľa pomeru veľmi silne. Potom je zmiačaný, zabalený veľmi pevne a umiestnený do kompaktného zásobníka drôtom alebo popruhami, aby bol ľahšie spracovateľný.

Existuje mnoho veľkostí kovových balíkov. Niektoré stroje môžu spracovať väčšie kusy kovu, zatiaľ čo iné sú určené na menšie kusy. Dokážu tiež spracovať iné typy starého kovu, vrátane aluminia z konzerv, miedze z káblov alebo ocele z starých spotrebičov. Ich chytré riadiace systémy im umožňujú aplikovať príslušnú rýchlosť a tlak, ktoré sa zhodujú s kvalitou každého kovu, čím sa zapojí do účinného procesu balenia.

Čo robí kompaktné kovové balíky také dobré?

Kompaktné kovové balikátory sú menšie ako bežné balikátory, čo ich robí ideálnymi pre podniky, ktoré nemajú veľa miesta. Dá sa ich použiť v úzších priestoroch, avšak stále vykonávajú svoju prácu. Tieto sú tiež systémy šetrné na peniaze, pretože ich spotreba energie je nižšia než u väčších strojov. To je dôležité pre podniky, ktoré hľadajú spôsoby zníženia nákladov. Znamená to tiež, že kompaktne balikátory majú nižšie náklady na údržbu a sú teda lacnejšie na dlhodobú údržbu.

Hlavný dôvod používania kovového balikátora je ten, že vám umožňuje spracovať hmotnejšie kovy. Keď zmačkáme kov do menších foriem, zaberie oveľa menej miesta. Pre stavebné a výrobné spoločnosti, ktoré vyrábajú veľké množstvo odpadného kovu, je to mimoriadne výhodné. Typicky produkujú odpadný kov v veľkých objemoch a balikátor môže pomôcť týmto odvetviam efektívne využívať ich odpadky.

Prostrednícke dôsledky kovových balikátorov: Ako im pomáhajú?

Stlačovanie kovu pre ekologicky orientované ďalšie veľké dôvody, prečo používať stlačovače kovu je to, že pomáha našej planete Zemi. Vyhladenia sú miesta na likvidáciu odpadu a vylodený zberkový kov takýmto spôsobom môže trvať dlho - aspoň stovky rokov - kým sa rozpadne. Do konca tohto obdobia môže kov vyvolávať škodlivé látky, ktoré prú do pôdy a vzduchu, čím ubližujú nášmu prostrediu.

Stlačovače kovu zrýchľujú proces recyklovania kovu, pretože je stlačený do hustejších materiálov. Kompaktný a usporiadaný kov je oveľa jednoduchšie dopraviť do centrál na recyklovanie. To zase znamená, že z planéte Zeme bude extrahovať sa oveľa menej prirodzeného, nového kovového materiálu, čo je obvykle energiovo náročné a potenciálne škodlivé pre životné prostredie. Predchádzame potrebe masového těženia a začínajúme zachovávať prirodzené zdroje pomocou ich znovupoužitia v podobe kovov cez recyklačné procesy.

Podľa veľkosti a typu dokážu metal balérovacie stroje vykonať mnoho úžasných vecí. Niektoré stroje sú navrhnuté pre veľké objemy second metals, zatiaľ čo iné fungujú najlepšie na malé množstvá. Môžu sa tiež prispôsobiť vytváraniu baliek rôznych veľkostí alebo hmotností podľa špecifických požiadaviek. Balérovacie stroje na kovy môžu byť vybavené aj ďalšími bezpečnostnými funkciami, vrátane bezpečnostných interlokov na ochranu pracovníkov a ohradami. To znamená, že podniky môžu mať istotu, že sú bezpečnosť pri ich používaní prioritou.

Výhody balení druhového kovu pre podnikanie

Balenie druhového kovu prináša podnikom a priemyslu mnoho ekonomických výhod. Usporiť sa dajú významné sumy na poplatkoch za prepravu a nákladoch na skladovanie. Pre veľké priemyselné odvetvia, ako je stavebníctvo a výroba, ktoré produkujú veľké množstvá druhového kovu, to znamená významné úspory. Kompatibilný druhový kov je jednoduchší a teda lacnejší na dopravu do recyklačných centrál.

Ďalší zdroj príjmov pre firmy je, že presunovanie kovu pri balení vytvára ďalší potenciálny zdroj príjmov. Môžu predať recyklovaný kov obchodníkom so starým kovom, čo im môže umožniť dosiahnuť zisk. Recyklovaný kov je lacnejší a ekologickýšie ako novodobýtaný kov, a preto je poptávka vyššia. To poskytuje podnikom nie len možnosť úsporiť peniaze, ale môžu tiež zarobiť na svojom starom kove.

Záver

Tieto nové kovové tlačidlá od Jiangyin Metallurgy sú prípravne vytvoriť revolúciu v spracovaní starého kovu danký svojmu kompaktnému a efektívnemu dizajnu. Všetko toto pomáha podnikom ušetriť spoustu peňazí a znížiť odpad. Sú extrémne významné, keď sa všetci snažíme starat o našu planetu lepším spôsobom. Týmto sa kovové tlačidlá znižujú odpady na skládkach, ktoré podniky vyvíja, a môžu dokonca vytvoriť nový zdroj príjmov predajom recyklovaného kovu. Kovové tlačidlá sú kľúčovým vybavením pre podniky, ktoré chcú znížiť svoje uhlíkové stopy, a keď sa postupne pohybujeme smerom k viac udržateľnosti a ochrane našeho prostredia, práca kovových tlačidiel bude len rásť.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

AZ

AZ

LA

LA

UZ

UZ