- Overview

- Parameter

- Features

- Inquiry

- Related Products

| Place of Origin: | Jiangyin, China |

| Brand Name: | Ecohydraulic |

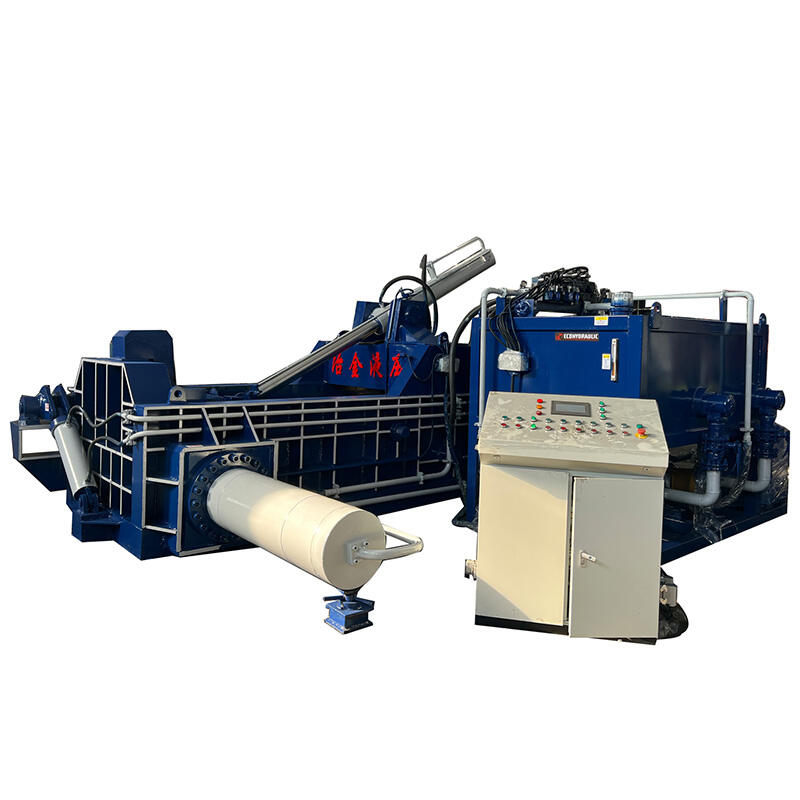

| Model Number: | Y81T-250PTZ |

| Certification: | ISO, CE |

| Minimum Order Quantity: | 1 set |

| Price: | FOB Shanghai, USD35000~USD38000 |

| Packaging Details: | Nude packing |

| Delivery Time: | 30 days |

| Payment Terms: | 30%T/T deposit, balance by T/T before shipment |

| Supply Ability: | 20 sets/month |

Application

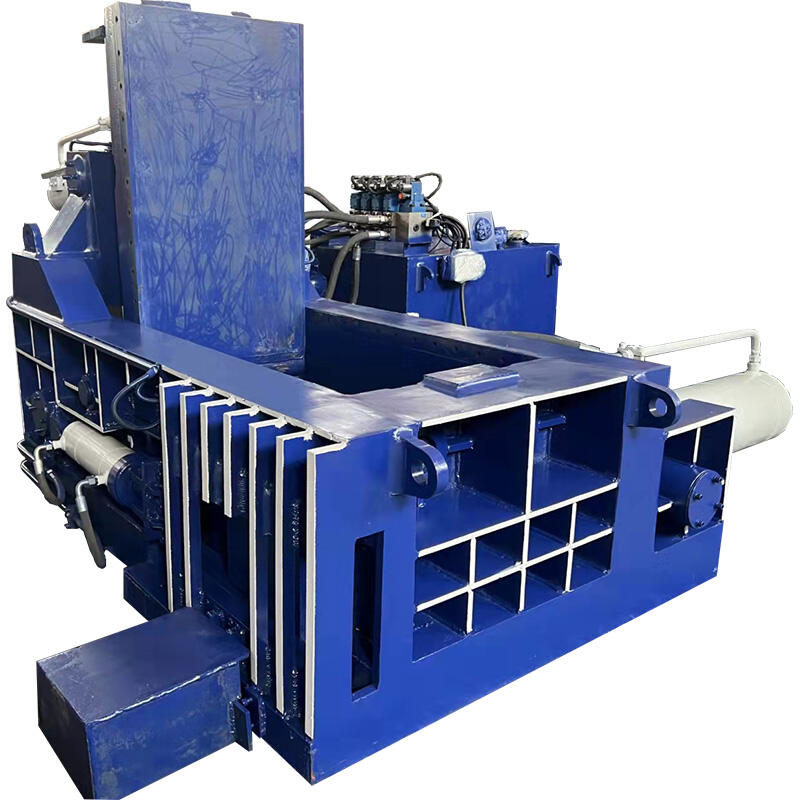

Cans Balers are widely used by recycling centers due to their efficient and proficient working mechanism. The larger aluminum can baler models can be customized to compress metal leftover, steel shavings and steel scraps. Furthermore, the optional manual and automatic control systems of the cans baler enable the automation of machine and allow the manual use as well. The choice is users.

Recycling aluminum cans, scraps, and tins are of supreme importance. Automatic Beer Can Metal Packing Compressing Machine is specially manufactured to compress aluminum waste into the cuboid shape. The compressing is done without any strapping which means there's no strapping materials cost and smelting cost involved.

In the past years, as people's sustainable development awareness has been continuously strengthened, more and more people have begun to pay attention to the recycling of resources. As one of the main machines in the metal recycling industry, metal balers can compress light metals into high-density metal blocks, which greatly save storage and transportatin space.

Specification

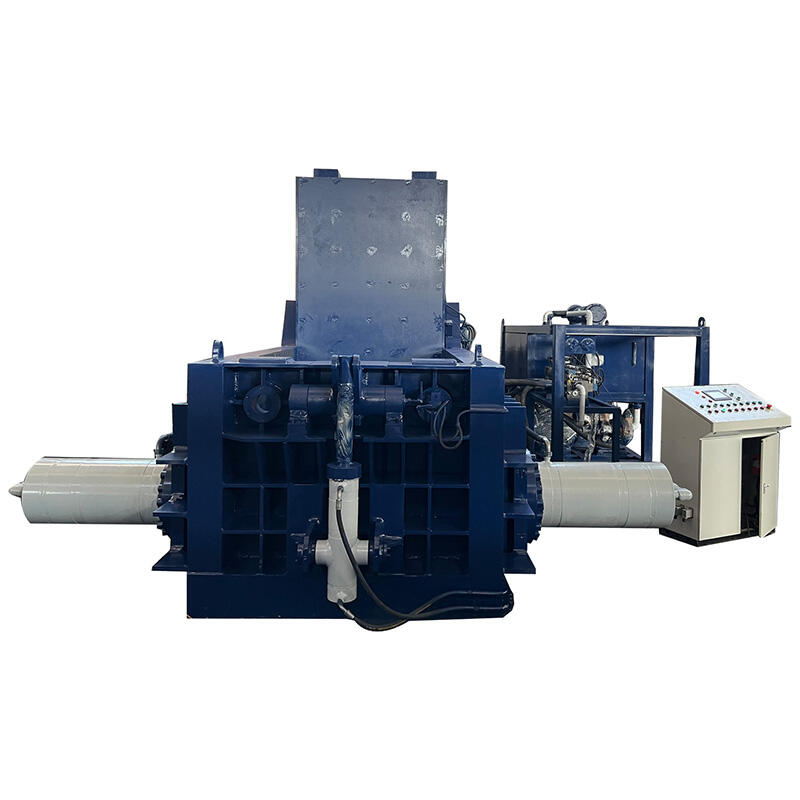

How does cans work? The motion program of the metal briquette machine is as follows:

1) the top cover is closed after filing, and it will be locked with a locking mechanism to prevent the top cover from being opened.

2) the master cylinder head accelerates forward and slowly advances after reaching the set stroke. Until the waste metal is packed into bales and equal to the length of the bales, the master cylinder maintains pressure at this time.

3) when the main cylinder is holding pressure, the side cylinder fast forwards, and when it reaches a certain position, it switches to slow forward. When the scrap metal is packed into a set width position, the rear cylinder holds the pressure.

4) after the packing is completed, the locking mechanism returns to its original position, and the upper cover is opened.

5) the pushing hydraulic shaft pushes the bale out of the machine's discharge room.

6) the front door is closed, immediately enter the next cycle and feed.

The cans baler is mainly composed of a hydraulic system, a control system, and a feeding system. The main parts are oil tanks, hydraulic telescopic boom, feeding chamber, side hydraulic rod, pressure plate, control panel, locking mechanism.

| model | Y81T-250PTZ |

| nominal force | 2500kn |

| press box size | 2000*1000*550mm |

| bale size | 550*550mm |

| Output | 18~19t/8h |

| production | 50~60s/bale |

| total power | 22kw*2 |

| machine weight | about 19ton |

Service

1) Free product documents translation into your language, worry-free to operate and maintain.

2) Engineers available to service machinery overseas.

3) Customer database with all customers' records in it.

4) 7*24 technical phone service.

5) One year guarantee and lifelong maintenance.

6) Spare parts: one set of spare parts for free, tool box, operation book.

FAQ

1) Are you a factory or a trade company?

We are manufacturer with own factory for more than 30 years.

2) How can I trust your company?

A. With professional design and sales team, we can serve you the perfect solution with lowest cost.

B. Assessed by third party, national patents for all equipment.

C. Welcome to inspect any time, we are near Shanghai airport.

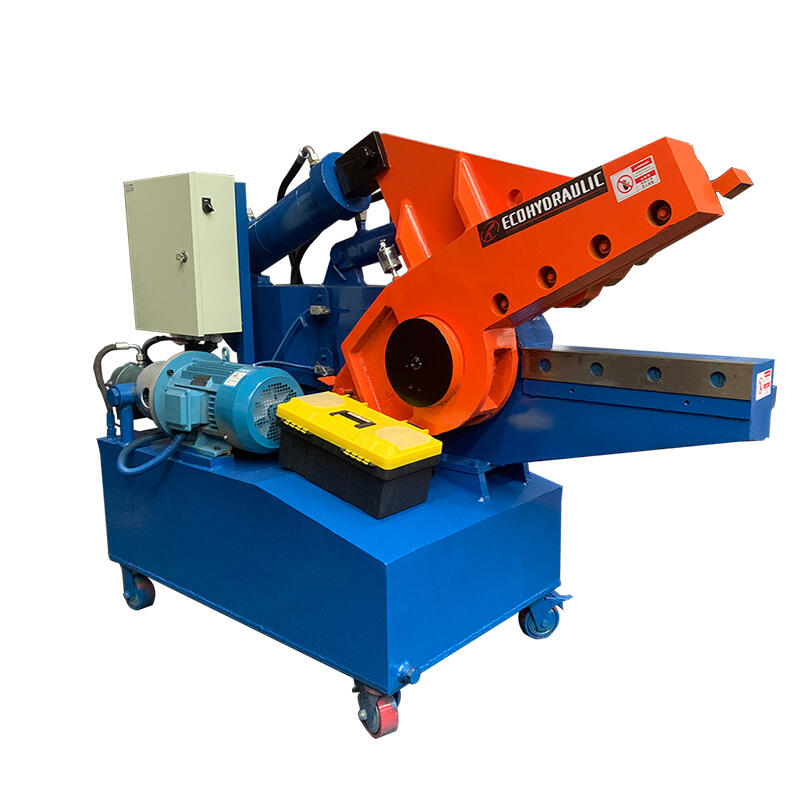

D. About the machine, we are the first manufacturer of briquette machine, hydraulic balers, alligator shears, shredders are also our main products.

3) Is your price competitive?

Surely we will give you best factory price based on superior product and service.

Contact us! We would like to tell you more about our cans baler.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

AZ

AZ

LA

LA

UZ

UZ