- Overview

- Parameter

- Features

- Inquiry

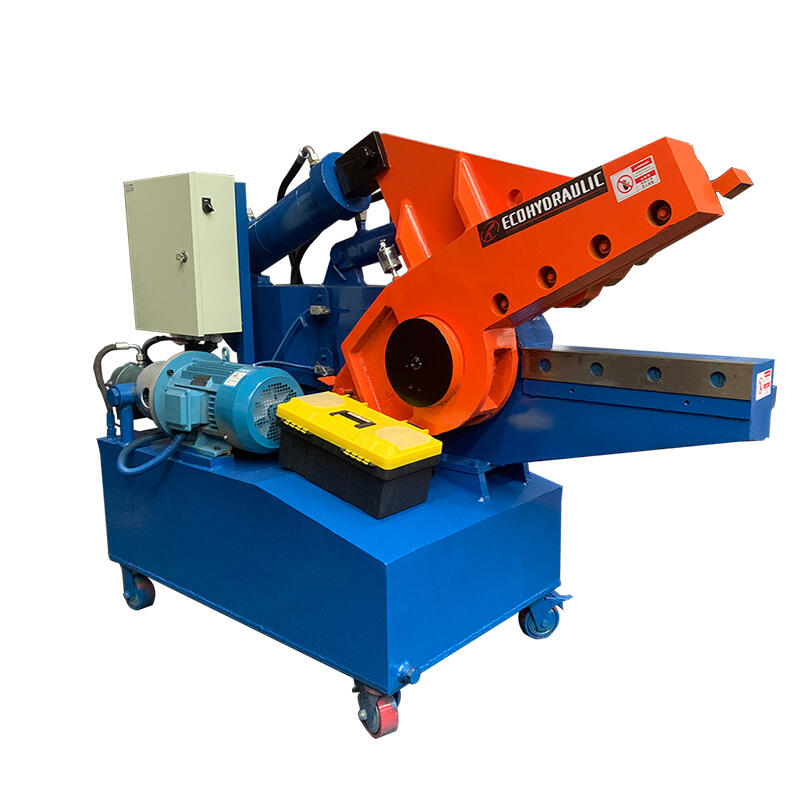

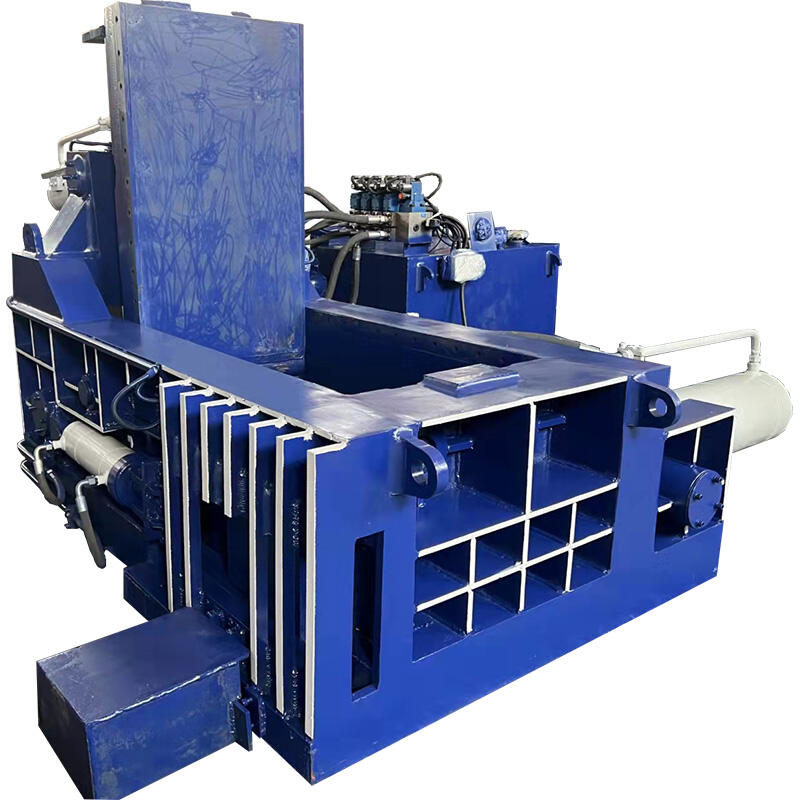

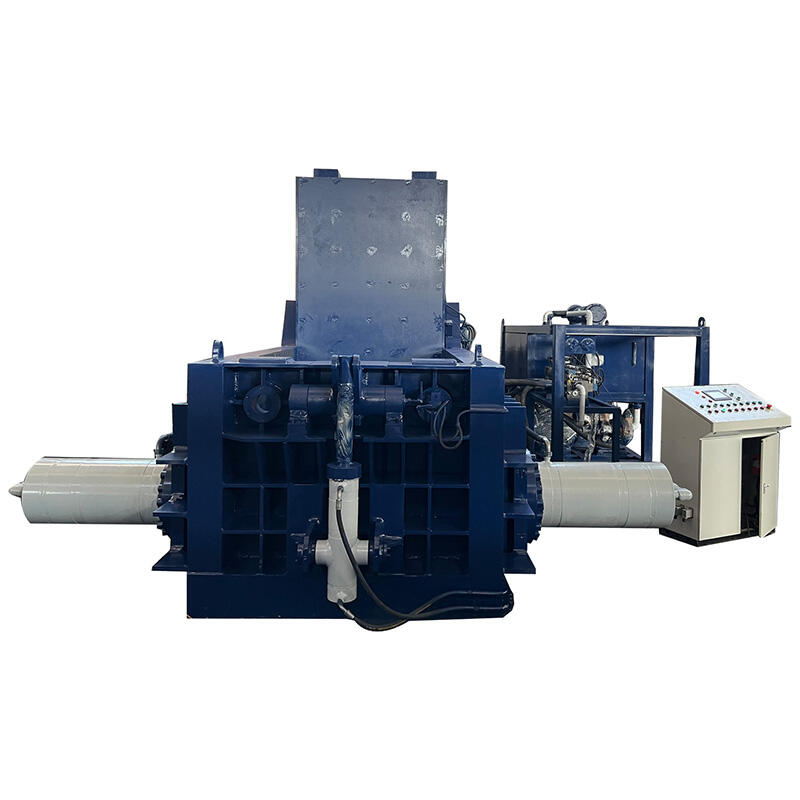

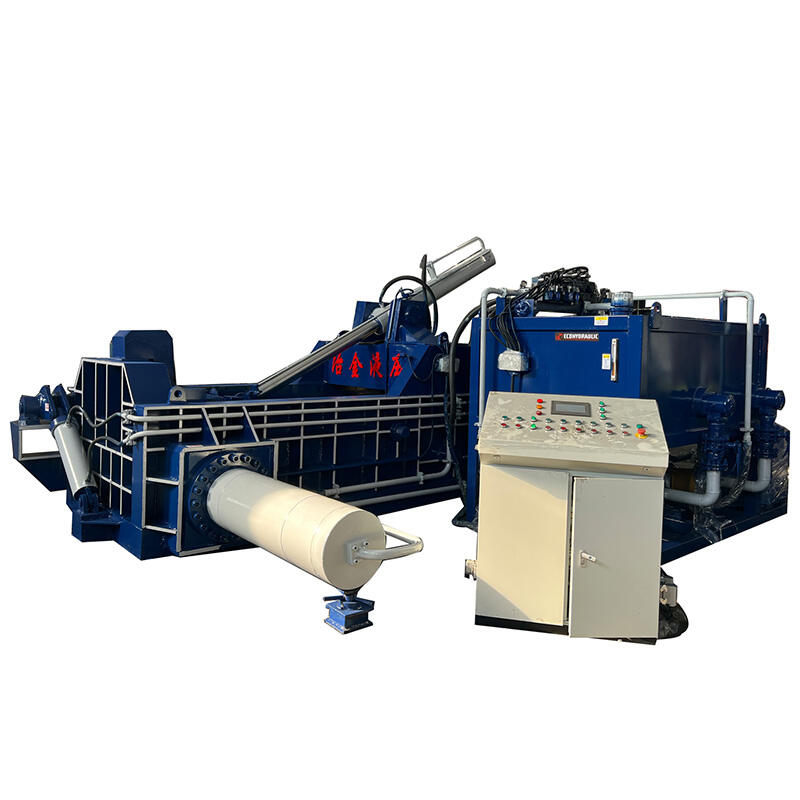

- Related Products

| Place of Origin: | Jiangyin, China |

| Brand Name: | Ecohydraulic |

| Model Number: | Y83-500 |

| Certification: | ISO, CE |

| Minimum Order Quantity: | 1 set |

| Price: | FOB Shanghai, USD28000~USD35000 |

| Packaging Details: | Nude packing |

| Delivery Time: | 15 days |

| Payment Terms: | 30%T/T deposit, balance by T/T before shipment |

| Supply Ability: | 30 sets/month |

Application

An iron briquette machine is a type of equipment used to compress iron powder into briquettes for easier transportation and storage. The machine uses high pressure to compact the iron powder into a solid form, making it more convenient to handle and transport. Iron briquettes are often used in steel mills and foundries as a raw material for the production of steel products.

1) product application for vertical briquetter

The briquetting process takes metal chips/swarf and compresses them under high pressure into a briquette form. Briquetting increases the value of your scrap metal and turns your scrap into an ongoing income stream. Briquetted material helps alleviate any potential cross contamination with other materials. Briquettes are almost free of coolant compared with loose chips and don't leak coolant during transportation around the factory. Storage costs are lowered as a result of the volume reduction achieved through briquetting. Briquetting your swarf allows a substantially more localized and tidy storage of your scrap, thus reducing your occupational health and safety risks.

2) pressed materials for briquette machine

cast iron, aluminum, copper, steel, brass, zinc, bronze, titanium, magnesium and other metal scraps.

3) advantages for vertical block making machine

- the high pressure reached in the compression chamber allows creating high density briquettes.

- besides drastically reducing the volume of the machining chips, remove cutting fluids and create briquettes.

- in most cases, briquettes can be placed directly in smelting furnaces.

- this results in substantial economic benefits for companies that generate the scraps, companies that recycle metal scraps, and for foundries that process the scraps.

- there are a large number of environmental benefits resulting from the briquetting process.

Specification

We recommend you a fully-automatic metal briquetting line, with conveyor, bunker, elevator, etc. Our Y83 vertical briquetting press has advantages as follows:

1) suitable for tiny metal scraps

2) with fast unit, hydraulic Acceleration System

3) High Briquet Density

4) Customized Accessories

5) Water Cooling or Air Cooling System

| model | Y83-500 |

| nominal force | 5000kn |

| briquette diameter | D120 (customized) |

| briquette density | ≥ 5.0t/m³ |

| briquette weight | 4~5kg |

| productivity | 3~4block/min |

| output in one shift | 6~7t/8h |

| total power | 22kw*2 |

| machine weight | about 9ton |

| overall dimension | host machine: 970*2500*4500mmoil tank: 1950*1500*1260mm |

Our service

1) Free product documents translation into your language, worry-free to operate and maintain.

2) Engineers available to service machinery overseas.

3) Customer database with all customers' records in it.

4) 7*24 technical phone service.

5) One year guarantee and lifelong maintenance.

6) Spare parts: one set of spare parts for free, tool box, operation book.

FAQ

1) Are you a factory or a trade company?

We are manufacturer with own factory for more than 30 years.

2) How can I trust your company?

A. With professional design and sales team, we can serve you the perfect solution with lowest cost.

B. Assessed by third party, national patents for all equipment.

C. Welcome to inspect any time, we are near Shanghai airport.

D. About the machine, we are the first manufacturer of briquette machine, hydraulic balers, alligator shears, shredders are also our main products.

3) Is your price competitive?

Surely we will give you best factory price based on superior product and service.

Contact us! We would like to tell you more about our metal briquetting system!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

AZ

AZ

LA

LA

UZ

UZ